InOut CHECKER 2.0 - the unique tool for commissioning of Siemens PLC systems!

InOut CHECKER helps you to test in a fast, user friendly and reliable way all inputs and outputs of the Siemens S7 300/400 or ET200s control system. What you will get:

- This program allows you to test all the signals and wiring WITHOUT your user program, unfriendly VAT tables, debugging or making of specific code.

- The personell with little or no programming experience could make tests. Ordinary electricians could conduct all the tests on site and meanwhile PLC-software engineers could continue to develop user program in their offices.

- Since this program is universal for all configurations, you can deliver and test the equipment without user program finished. This means in the lot of cases that you can make partial payment from the Client before schedule.

- You don't need any external signal generator. InOutChecker will generate all what you need.

- User friendly environment will speed up testing process and give a good impression on Client on FAT or SAT.

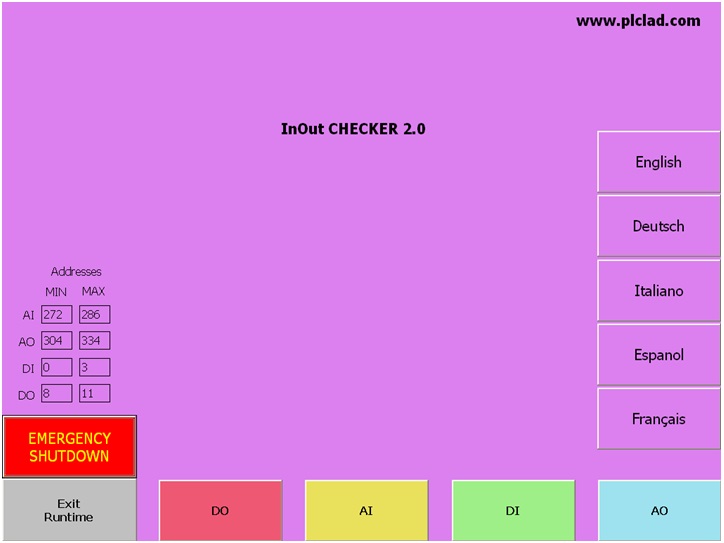

The aplication has the following languages: English, French, German, Italian, Spanish. The Manual is only in English.

Typicaly, this program serves in the following situations:

- The internal test of the new developed cabinet in the workshop.

- The formal Factory Acceptance Test with Client personell onboard.

- The internal test of the cabinet, wired cables and instrumentation on site.

- The installation part of formal Site Acceptance Test with Client personell.

This program comes with the following:

- Empty S7 project with S7 program blocks.

- Runtime SCADA file. Depending of the your license, you will use WinCC V12, WinCCFlexible 2008 SP2/3 or Protool aplication. You can use MPI or Ethernet.

- The Manual.

- Validation Test Report.

- On special demand: the copy of executed Operational Qualification Protocol-InOut Checker 2.0.

What you need:

- Step 7 V5.5 or higher – for making of your own HW Config and downolad of S7 blocks.

- SCADA Runtime License (WinCC, WinCC Flexible, Protool). This you obtain normaly for the End User for your own SCADA program. InOutChecker needs the smallest license.

See detailed manual or video tutorial.

Here you can see in a brief how InOut CHECKER works.

The Main screen allows you to choose language, and set address area – according to your aplication.

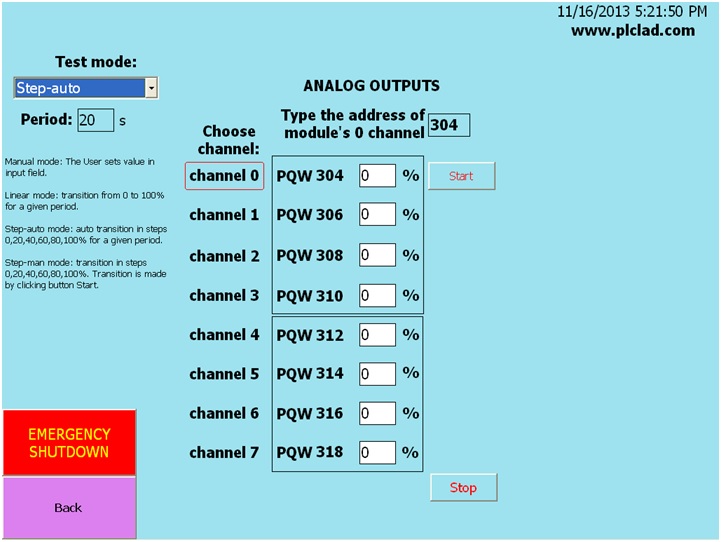

The AO screen allows to test all analog outputs in several different modes. You can set outputs in manual mode, or you can choose linear or step generation of output. Linear and step outputs are particulary useful when you test settings and behavior of devices such as dampers, valves and motors.

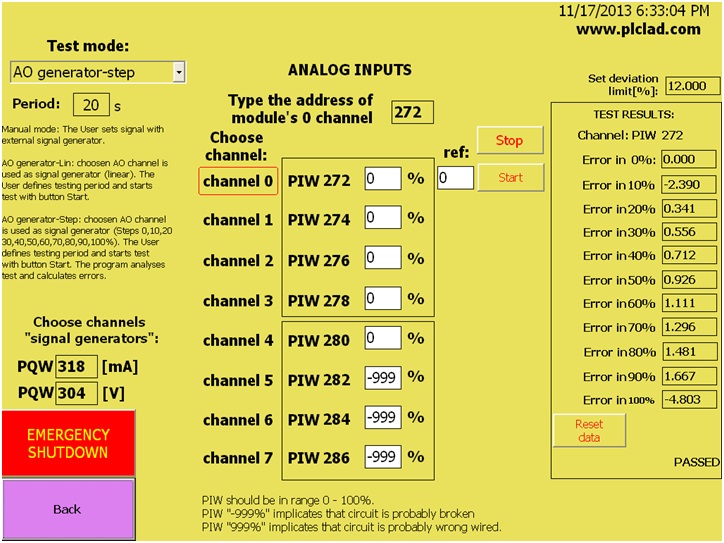

The AI screen allows to test all analog inputs in several different modes. You can use manual mode by using external signal generator connected to terminal assemblies and watch results in this screen. The other possibilities are real impovement in the work – you can choose some analog output channels as a reference. You wire reference channel with testing measurement channel and start the test. The program generates linear or step signal. Even more, the program analyses measuring and calculates DA/AD error in 11 points.

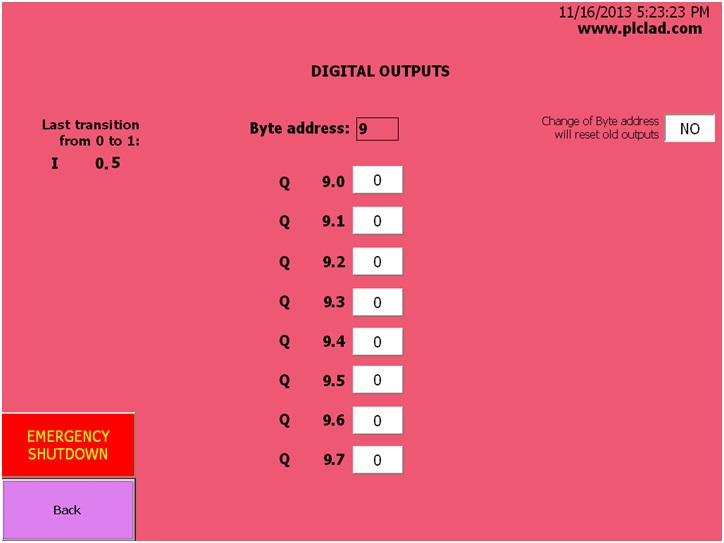

The DO screen is made for testing of digital outputs. For the safety reason, the program will reset old outputs when you change byte address. This can be ommited with a special switch. In that case, "the old" outputs would not be reseted – this could be useful during site tests. There is also "Emergency shutdown" on each screen. This button will reset all digital and analog outputs. Another useful feature is a detection of a last digital input change from 0 to 1. When you switch on some output you will probably initiate some feedback and this feature can show you this reaction.

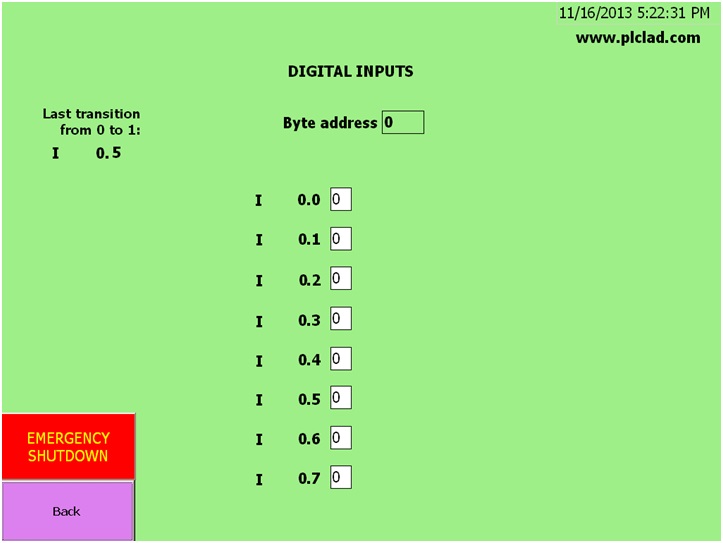

The DI screen is made for testing of digital inputs. You can observe the behavior byte by bite, or you can use the feature of a detection of the last digital input change. Don't belive to the LEDs on the module, the only important thing is what is seen by PLC!

Siemens PRONETA

Very recently Siemens launched Proneta tool. This program is intended only for ET200s. If you need just a basic operations with inputs and outputs (reading and writing) it is worth to try it. You can start from Siemens forum thread.